Project

Insects as food ingredients

Yellow mealworm paste can be produced with diverse textures, which offers possibilities for the development of products like insect burgers and spreads.

Introduction

The food and feed industry is interested in alternative protein sources. Insects, with a protein concentration of 30-70% on a dry weight basis, are an attractive option, also from the perspective of circular economics.

Ensure microbial safety and prevent browning

In order to use insects as food ingredients, amongst others (see frame) two hurdles have to be overcome: microbial safety and browning. Browning of mealworms occurs due to the presence of the enzyme polyphenoloxidase. We performed experiments with yellow mealworms (Tenebrio molitor), addressing these two aspects, followed by an investigation of texturization.

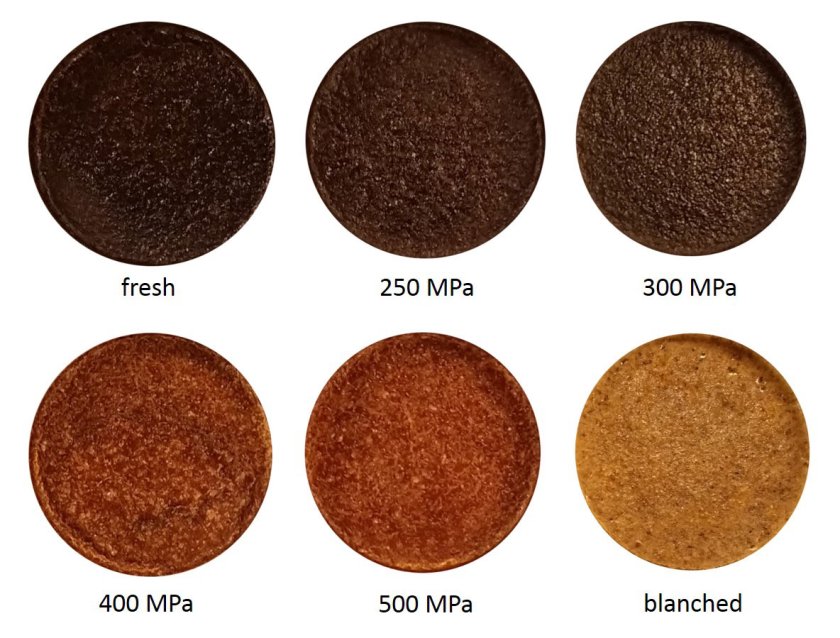

In our experiments, different blanching and high pressure treatments - a relatively new mild preservation technique - were tested on whole mealworms. The mealworms were then ground into paste in order to evaluate the effect of the treatments on browning. The best conditions that prevented browning were a) short blanching with a peak temperature of 80°C, or b) a high-pressure treatment with pressures of > 400 MPa (4000 bar). The side effect of blanching is a soft textured mealworm paste, whereas high-pressure treatment resulted in a harder and drier texture. Browning could also be prevented by air-tight packaging.

Custom-made texture and product application

Combining the results of blanching and high pressure treatments allows us to tailor the texture of the mealworm product. For a spread, the colour should be light and the texture should be soft. Therefore blanching is the best method. For a burger, browning and a firmer texture are desirable, so the advice is a high-pressure treatment at 400 MPa (4000 bar). Another option would be no treatment at all. In this case, microbial safety can be assured by heating the mealworm burger in the pan. A burger should be somewhat crumbly and release some, but not too much moisture. Both mealworm burgers meets these requirements. A pâté type of texture can be achieved with mealworms, when high pressure treatment at 500 MPa (5000 bar) is applied.

In the laboratory tests, high pressure treated mealworms showed an appealing orange / light brown colour, and the aroma of mealworm paste was savoury, with a mushroom and nut note. Upon baking, the aroma even intensified. These properties, combined with the excellent nutritional values, supports our beliefs that mealworm paste has a future as food ingredient on the meat replacer market.