Project

Food product design through powder based 3D printing

How can powder based 3D printing technology be used to make food products with new functionalities and properties? And what other advantages may this innovative food process offer?

Background

Personalization and consumer empowerment are important drivers for the interest in additive manufacturing (3D printing) for local on-demand, flexible food production. Amongst additive manufacturing techniques, powder based printing is one of the most promising in terms of its added value over traditional food processing methods and of its scalability. Powderbed printing is currently employed for manufacturing of non-food materials (plastics, metals) but in the food domain, however, this technique is applied in very limited cases until now. TNO and WFBR developed an innovative powderbed printing facility which became recently available for food research activities.

Overall intention, goal, and innovation

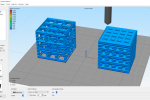

The goal of this project is to enable the manufacture of food products with specifically designed functional properties by means of powder-based 3D printing techniques. These technologies include powder bed printing (PBP), selective laser sintering (SLS), and their combination.

Rather than using traditional methods to create functional properties in food products, here a digital route will be developed through which food product designs and structures, and their functional properties can be created digitally, and then realized via state-of-the art 3D printing technologies. This new digital method will not only allow for the rapid creation of prototypes of new innovative food product concepts with surprising functionalities, but will also provide the agri-food industry with a means to deliver personalized, on-demand, healthier food products in a manner that is more responsive to consumer, environmental and societal needs.

The project will use an applied scientific approach in which food material science, as well as process and software engineering capabilities are combined. Hence, the industrial partners (global food ingredient and pet food companies) and the knowledge institutes (Wageningen University & Research and TNO Eindhoven) form a highly suited consortium. Together, the consortium will exploit the potentials of powder-based 3D printing technologies for food manufacturing. This project will result in:

- a dedicated powder based additive manufacturing process for food

- a knowledge base to control food structure properties (based on ingredient and printing parameters)

- food product prototypes with functional aspects (physical and sensorial) that can be digitally designed and controlled

Impact

We will investigate powderbed printing as a novel and sustainable production process and demonstrate its unique capabilities for the creation of personalized food products with optimized nutrient composition and for customized functional properties. This consortium project will create the first essential tools that will allow the use of this technology for the manufacture of personalized, on-demand food in the near future.